Diamond Slurries For General Purposes / Diamond Slurries For Specific Applications

DYNAQUAL™ AND HYDROQUAL™

DYNAQUAL™ POLYCRYSTALLINE DIAMOND SLURRY

Dynaqual Advanced Polycrystalline (DAPD) Diamond Slurry - Third generation polycrystalline diamond slurry made with surface-modified diamond particles in an advanced formulation matrix suitable for high-precision lapping and polishing a variety of substrates.

DYNAQUAL™ MONOCRYSTALLINE DIAMOND SLURRY

Dynaqual Advanced Monocrystalline (DAMD) Diamond Slurry - Third generation monocrystalline diamond slurry made with surface-modified diamond particles in an advanced formulation matrix suitable for high-precision lapping and polishing a variety of substrates.

HAPD POLY-D SLURRIES

Hydroqual Advanced Polycrystalline (HAPD) Diamond Slurry -Hydro-based polycrystalline diamond slurry made with detonation-synthesis diamond particles in an advanced formulation matrix suitable for high precision lapping and polishing of materials not too high on the Mohs scale.

HAPH POLY-H SLURRIES

Hydroqual Advanced Polycrystalline (HAPH) Diamond Slurry - Hydro-based polycrystalline diamond slurry made with high-pressure high-temperature diamond particles in an advanced formulation matrix suitable for high precision lapping and polishing of materials not too high on the Mohs scale.

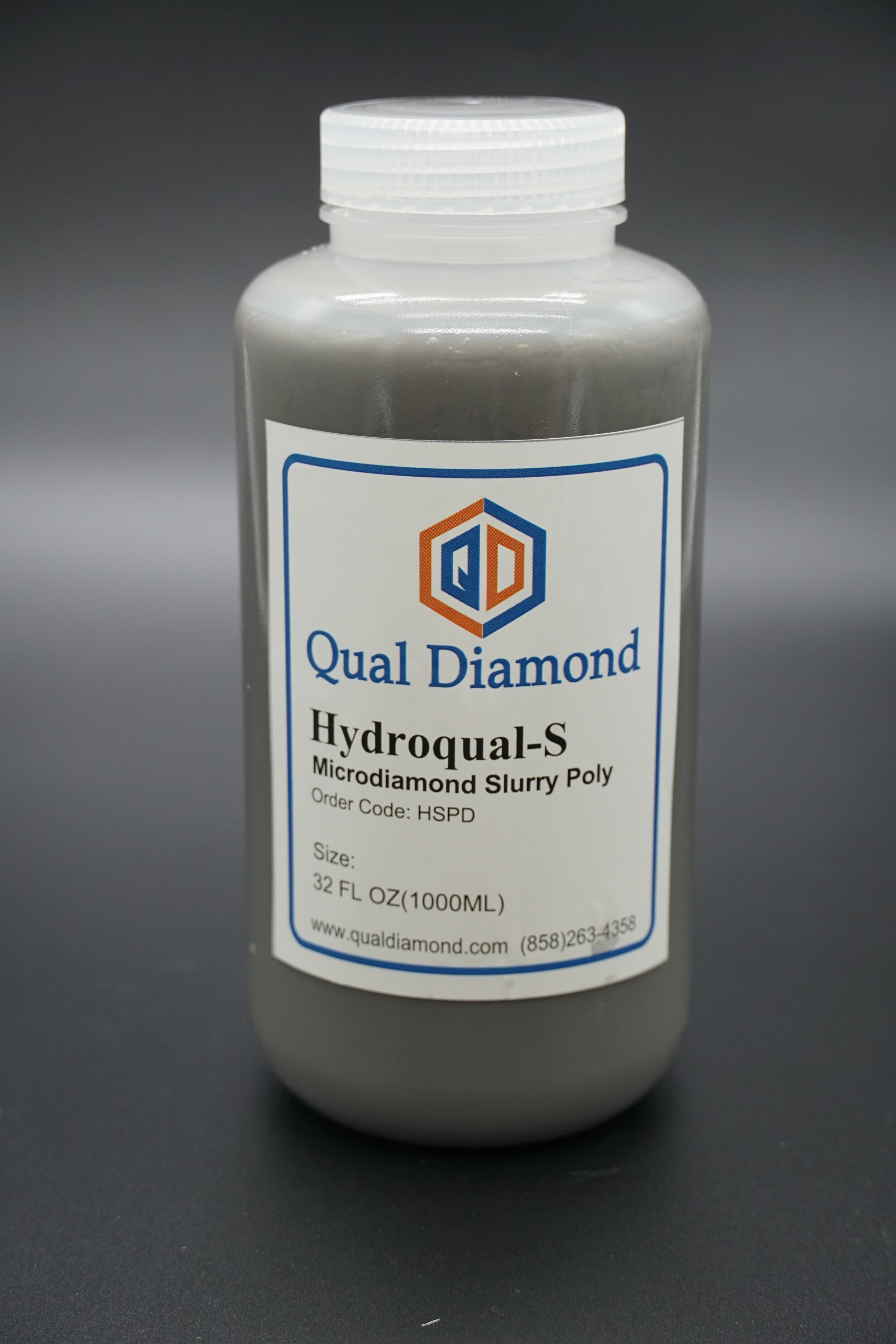

HSPD POLY-D SLURRIES

Hydroqual Standard Polycrystalline (HSPD) Diamond Slurry - Hydro-based polycrystalline diamond slurry made with dentonation-synthesis diamond particles in a standard formulation matrix suitable for high precision lapping and polishing of materials not too high on the Mohs scale.

HSPH POLY-H SLURRIES

Hydroqual Standard Polycrystalline (HSPH) Diamond Slurry - Hydro-based polycrystalline diamond slurry made with high-pressure high-temperature diamond particles in a standard formulation matrix suitable for high precision lapping and polishing of materials not too high on the Mohs scale.

HAM DIAMOND SLURRIES

Hydroqual Advanced Monocrystalline (HAM) Diamond Slurry - Hydro-based monocrystalline diamond slurry made with high-pressure high-temperature diamond particles in an advanced formulation matrix suitable for high precision lapping and polishing of materials high on the Mohs scale.

HSM DIAMOND SLURRIES

Hydroqual Standard Monocrystalline (HSM) Diamond Slurry - Hydro-based monocrystalline diamond slurry made with high-pressure high-temperature diamond particles in a standard formulation matrix suitable for high precision lapping and polishing of materials high on the Mohs scale.