Overview

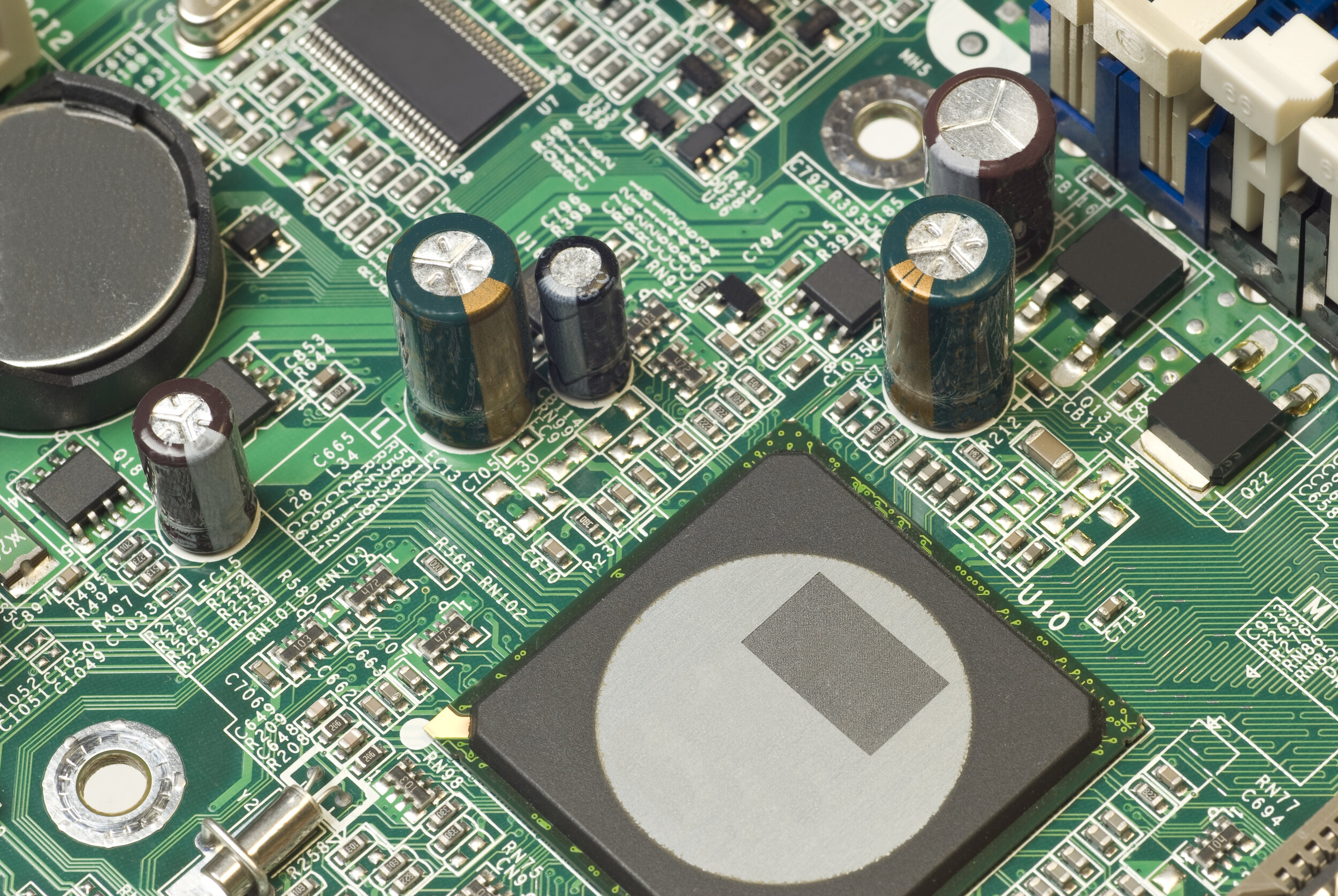

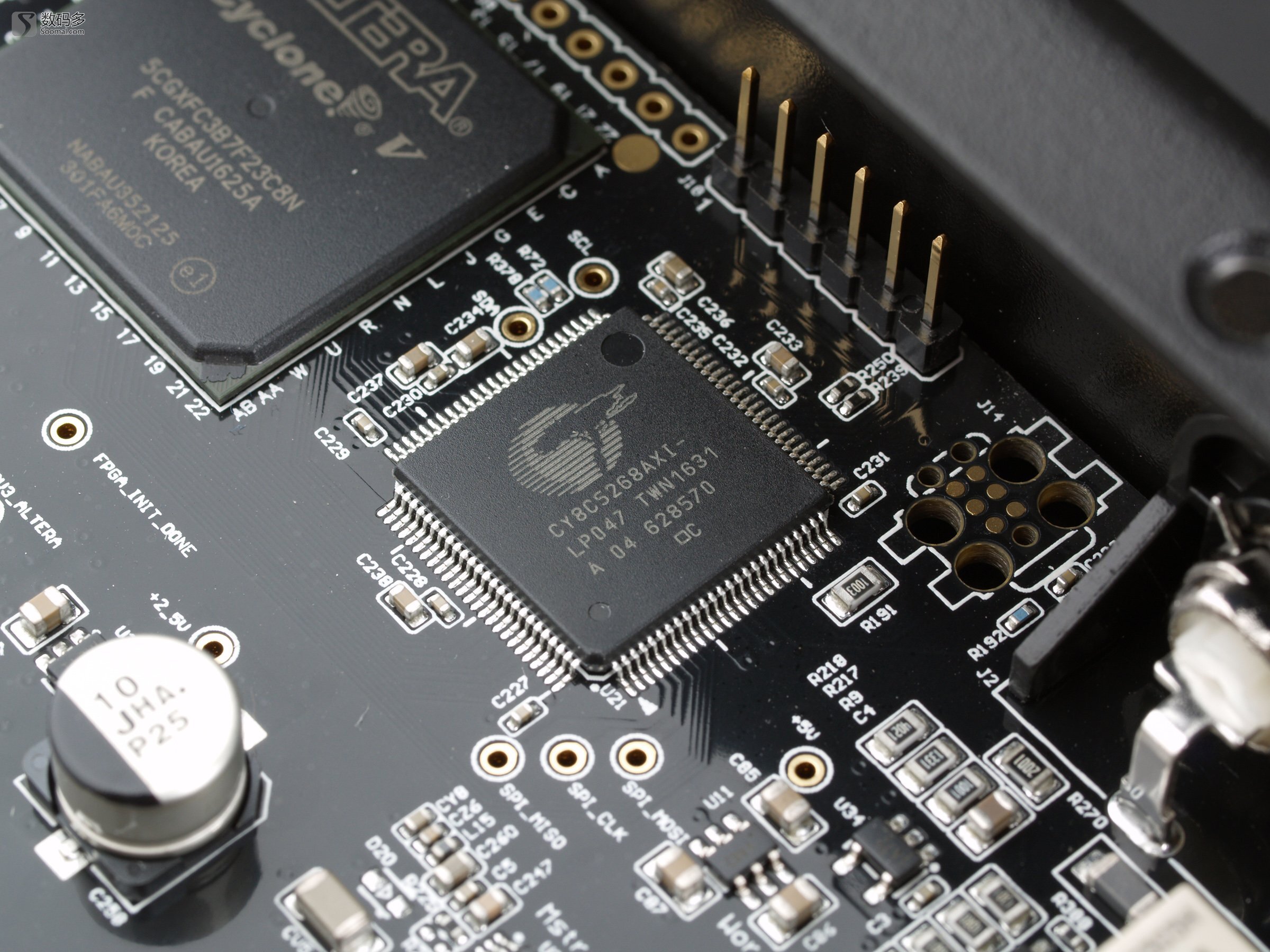

Advances in wafer fabrication, simulation, MEMS, and nanomanufacturing have ushered in a new era in semiconductor industry. However, the thinning of silicon wafer is still being carried out by mechanical lapping and precision polishing. Even though the number of electronic apparatuses, such as those used in PCB manufacturing, has grown significantly, challenges in machining prescribed thickness and roughness remain.

THE ADVANTAGES OF QUAL DIAMOND SLURRY AND POWDER

Qual Diamond diamond particles are treated with proprietary surface chemistry. Specially formulated matrixes are crafted for different diamond slurries for different applications. Our ISO-compliant quality control procedures, which include stringent sizing protocols and elemental analyses, ensure tight diamond particle size distribution and high-level of diamond purity. These advantages translate into faster material removal rates, achievement of tight tolerances, consistent results, and cost savings.

● Non-agglomeration due to advanced surface treatment of diamond particles.

● Tight size distribution due to stringent sizing protocols.

● High-level of diamond purity due to stringent quality control.

● High material removal rate due to non-agglomeration of diamond particles.

● Specially formulated for precision polishing with pitch, plate, and pad.

● Eco-friendly formulation requires only water for cleaning procedures

SILICON WAFER LAPPING AND POLISHING

Silicon wafers are widely used in the semiconductor industry. The requirement of uniform edge-to-edge thickness of a wafer work piece means tight tolerance for lapping and precision polishing and remains a major challenge. Uneven machined thickness is also detected using edge detection technology on PCB boards, hard drives, computer peripherals, and other electronic components and remains a challenging aspect of manufacturing. The majority of machines used in lapping and precision polishing silicon wafers are fully automated planetary polishing machines. They are designed for different sizes of wafers and equipped with automatic slurry dispensing capability.

Diamond slurry is an excellent material removal and thinning agent for semiconductor and electronic components. As the hardest material on earth, diamond particles in slurry render high removal efficiency and exceptional surface finish. Wafer thinning can start with planarization with diamond slurries of a larger grit size, followed by sub-micron size slurries for the final stages of precision polishing.