Overview

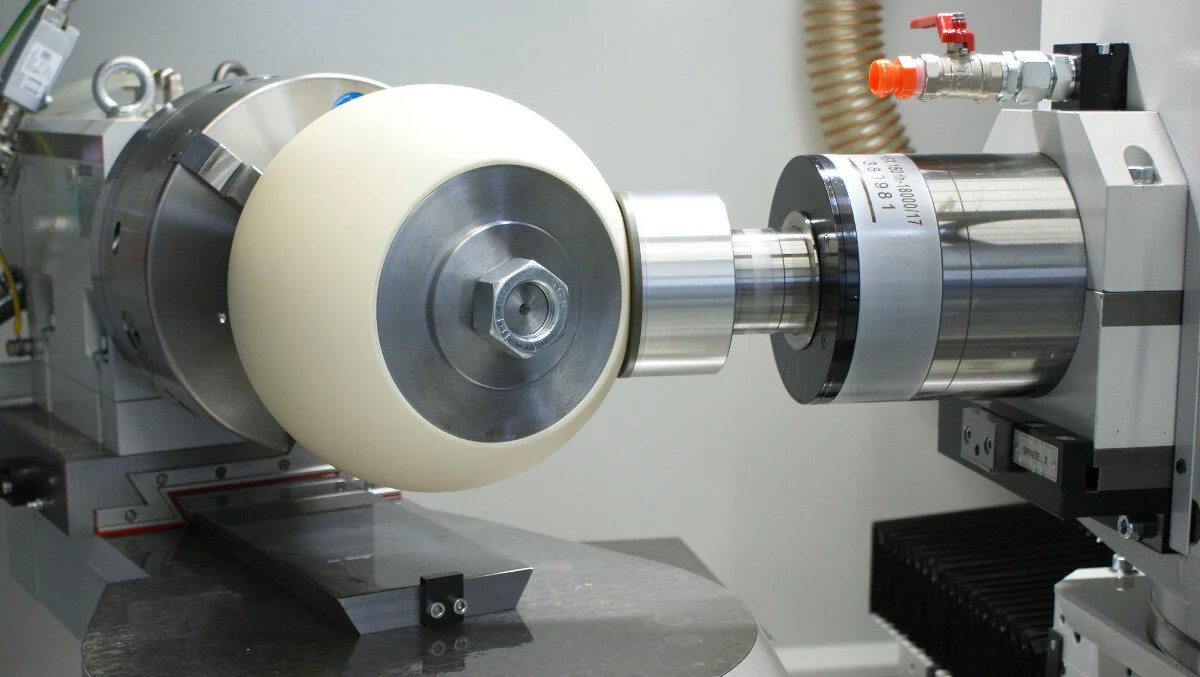

As countries race to send robots to the surface of Mars and billionaires vow to make the human species an interplanetary species, the aerospace industry is poised to be one of the fastest growing enterprises of human endeavors. The driving force behind the aerospace industry will also propel other industries such as electronics, telecommunications, aviation, oil and gas, defense, and medical devices forward. These industries demand a large quantity of advanced ceramic and composite materials.

The commonly encountered advanced ceramic materials are silicon carbide, aluminum nitride, alumina, zirconia, titania, mercury cadmium telluride, boron carbide, silicon nitride, tungsten carbide, and silicates. These materials are commonly found in electronic and electrical equipment due to their strong electrical conductivity and high corrosion resistance. They are also used in body armor, cutting tools, and engines. Advanced composite materials are commonly used in space vehicles, aircrafts, and drones. Composite material, in its simplest form, is composed of reinforcement and matrix. The matrix is the weaker material and is embedded in the stronger material, the reinforcement, to provide orientation and directionality. The strength and lightness of advanced composite materials are the main advantages over other materials.

THE ADVANTAGES OF QUAL DIAMOND SLURRY AND POWDER

Qual Diamond diamond particles are treated with proprietary surface chemistry. Specially formulated matrixes are crafted for different diamond slurries for different applications. Our ISO-compliant quality control procedures, which include stringent sizing protocols and elemental analyses, ensure tight diamond particle size distribution and high-level of diamond purity. These advantages translate into faster material removal rates, achievement of tight tolerances, consistent results, and cost savings.

● Non-agglomeration due to advanced surface treatment of diamond particles.

● Tight size distribution due to stringent sizing protocols.

● High-level of diamond purity due to stringent quality control.

● High material removal rate due to non-agglomeration of diamond particles.

● Specially formulated for precision polishing with pitch, plate, and pad.

● Eco-friendly formulation requires only water for cleaning procedures

APPLICATIONS OF DIAMOND ABRASIVES

As the number of new advanced ceramic materials continue to increase in the market, the demands for precision polishing also skyrocket. The high hardness values of advanced ceramic materials make precision polishing with abrasives other than diamond challenging. Diamond abrasives in the form of slurry are often the choice when it comes to precision polishing of advanced ceramic materials. Since advanced composite materials are often used in aeronautics, the high-precision requirements and finishes in machining are critical and challenging at the same time. Besides being used for lapping and polishing, diamond slurries are also used in polishing to reveal microstructural integrity in metal matrix composites such as SiC/Ti, AlSiC, and Ti-6Ak-4V alloys . Furthermore, diamond slurries are often used to planarize surfaces of advanced composite materials to provide a seamless joining of parts.